Application

Blast furnace electric isolation valve is suitable for complete isolation of toxic, harmful and flammable gas pipelines in metallurgical industry, chemical industry and environmental protection industry.

Control Principle

1. Blast furnace electric isolation valve uses explosion-proof electric drive. Considering the condition on site, electric drive can be equipped with sprocket to realize remote and manual operation safely. (Sprocket is equipped on request.)

2. The material of expansible joint can be specified by users according to exact condition. The expansible joint is made of 316L stainless steel if unspecified.

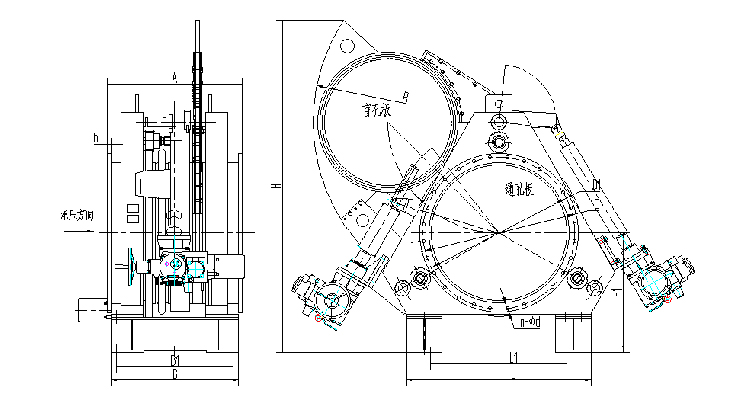

| DN | D | D1 | n- φd | H1 | A | B | B1 | L | L1 | H | R | b | Weight(KG) |

| 600 | 775 | 705 | 20-26 | 870 | 600 | 600 | 520 | 830 | 680 | 1680 | 928 | 22 | 1600 |

| 700 | 860 | 810 | 24-26 | 860 | 750 | 700 | 620 | 880 | 780 | 1820 | 1030 | 22 | 1800 |

| 800 | 975 | 920 | 24-30 | 950 | 800 | 800 | 700 | 1135 | 1030 | 2285 | 1172 | 22 | 2550 |

| 900 | 1075 | 1020 | 24-30 | 985 | 800 | 800 | 700 | 1135 | 1030 | 2460 | 1298 | 22 | 2900 |

| 1000 | 1175 | 1120 | 28-30 | 880 | 1000 | 940 | 860 | 1360 | 1010 | 3462 | 1424 | 26 | 3350 |

| 1100 | 1275 | 1220 | 28-30 | 930 | 1000 | 940 | 860 | 1485 | 1135 | 2767 | 1512 | 26 | 3400 |

| 1200 | 1375 | 1320 | 32-30 | 980 | 1000 | 940 | 860 | 1605 | 1255 | 2924 | 1642 | 26 | 3700 |

| 1300 | 1475 | 1420 | 32-30 | 1030 | 1000 | 940 | 860 | 1730 | 1380 | 3050 | 1724 | 26 | 3900 |

| 1400 | 1575 | 1520 | 36-30 | 1100 | 1000 | 1000 | 940 | 1850 | 1450 | 3221 | 1843 | 26 | 4300 |

| 1500 | 1690 | 1630 | 36-30 | 1150 | 1000 | 1000 | 940 | 2015 | 1615 | 3254 | 1952 | 26 | 5000 |

| 1600 | 1790 | 1730 | 40-30 | 1200 | 1000 | 1000 | 940 | 2190 | 1790 | 3471 | 2080 | 26 | 5700 |

Features

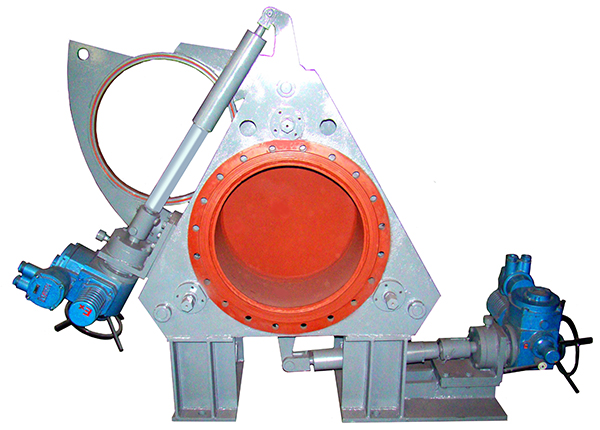

1. Blast furnace electric isolation valve is made up of valve body, valve plate, screw nuts on the left and right sides of draw bar, screw rod, valve base and electric drive.

2. The front, middle and rear parts of the blast furnace electric isolation valve adopt the structure of welded steel plate. They feature excellent rigidity and light weight. The front, middle and rear parts are connected together through draw bar, and are fixed to the valve base through bolts, so that the blast furnace electric isolation valve has a rigid structure.

3. The stainless steel expansible joint is installed between the front and middle part of the valve to realize the adjustable loosening or clamping of the valve parts. The front part of valve and middle part of valve are connected to thread screw, so that the middle part of valve can compact or separate the rear part of valve and valve plate alone.

The clamping and separating is realized by the electric drive, which drives draw bar to rotate the screw rod through gear ring.