Blast furnace material distributor includes electric distributor and hydraulic distributor.

Electric blast furnace material distributor

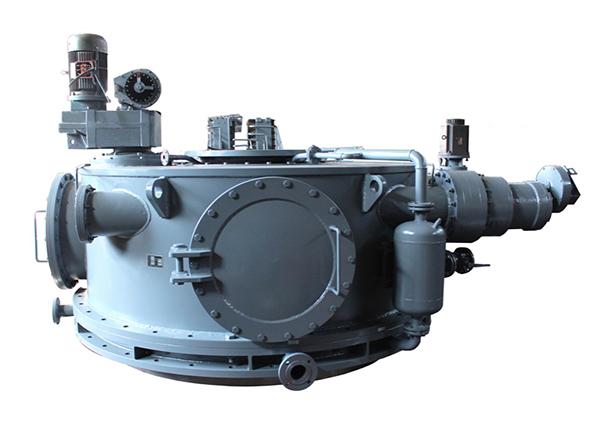

Material distributor, also known as distributing airtight box, is the core equipment of the blast furnace. It controls the tilt angle α and rotation angle β of the chute to achieve a flexible and diverse distribution of materials.

1.1 The Y series motor drives the reducer to cause the rotation (β) of chute. The chute rotates to drive the rotation of small pinion in the inserting box and rotary sleeve. The chute is hung in the bottom of the rotating sleeve to realize the rotation of chute.

1.2 The tilting (α) of the chute is driven by the AC servo motor or variable frequency motor.

Note:

a. Rotation and tilting can be carried out separately. They can also simultaneously keep rotating while tilting, or tilting while rotating. So it meets various requirements for distribution of blast furnace.

b. The two standard reducers that drive α and β are installed outside the distributor, which facilitates replacement of reducer. The internal distributor is driven by connecting rod. It has a simple structure and is more suitable for the condition of internal distributor.

c. Water cooling system uses a new cooling method: closed water-cooled chassis plus open water-cooled spray pipe. The heating surface inside the distributor direct contacts the cooling water. The cooling intensity is strong and it cools water with a speed of 3 cubic meters / hour. Water quality meets the quality standard of industrial purified water.

d. The floating through the seal ring automatically compensate for the nitrogen, which effectively prevents the coal gas containing dust at the furnace top from flowing into the airtight box. The amount of nitrogen usage is only 20-60 cubic meters / hour.

e. Lubrication pipeline is installed to all the components, so that the parts of distributor will be lubricated completely.

Hydraulic blast furnace material distributor

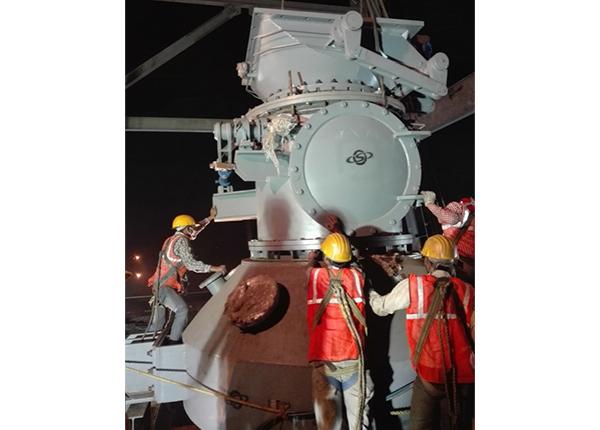

The hydraulic distributor is the other transmission structure designed on the basis of the electric distributor. The titling of chute is driven by the hydraulic cylinder. The three hydraulic cylinders drive internal brackets to operate upward and downward to realize tilting of chute. Hydraulic distributor has less parts and the transmission chain is shorter.

Hydraulic distributor shares the same structure, water cooling technology and nitrogen sealing technology with and electric distributor. The parts are interchangeable.

Application