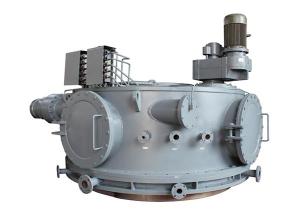

Rotary seal valve is one of the key equipment for coke dry quenching projects in coking plant, which is always installed on the bottom part of the CDQ boiler (coke dry quenching).

Since material inlet is connected with vibrating feeder, and material outlet is connected with decoking chute, these connections all need a good sealing. Therefore, rotary seal valve is installed, which enables a continuous exhaust of coke under an airtight environment. The design does not only provide a high sealing and good wear-resistance, it also enables a stable discharging.

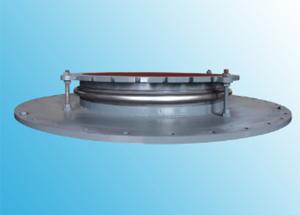

Rotary seal valve is mainly composed of valve body, rotor, seal seat, drive unit and automatic grease feeder. And rotary seal valve could be fixed on a movable handcar, which could transfer the valve to maintenance platform along the pre-laid course. The design enables an easy and convenient repair.

1. Materials' discharging is delivered by coupling, which leads to the rotating of rotors. Besides that, a wear-resistant lining is also installed on the surface of valve body and rotor.

2. Metal hard seal design is adopted for the connection of valve body and rotor, which provides a good sealing for valves.

TINITE also provides solutions for blast furnace charging equipment, and various large valves for industrial field.

TINITE sincerely welcomes your contact.