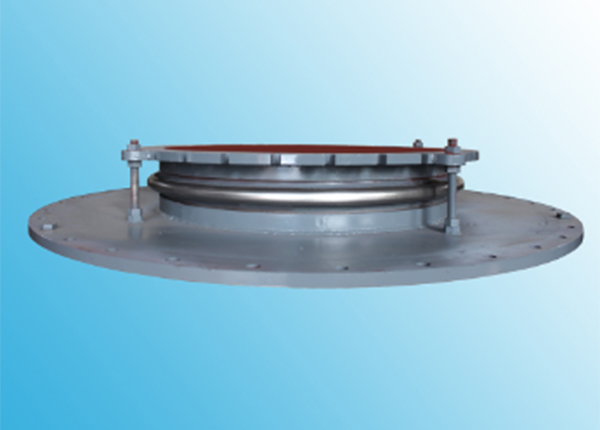

Top metal bellows expansion joint: Top metal bellows expansion joint is a thermal compensation device, which provides much convenience for the machine's maintenance and repair. The top metal bellows expansion joint is usually installed with one or two bellows, and the row material of the expansion joint is corrosion-resistant stainless steel plates. Top metal bellows expansion joint is mainly used for two purposes:

1. Withstanding the stress caused by thermal expansion and contraction

2. There is an empty space left inside the top metal bellows expansion joint, which provides much convenience for the maintenance and repair of the burden valve and upper sealing valve.

Bottom metal bellows expansion joint: Bottom metal bellows expansion joint is mainly designed to compensate the axial displacement and radical displacement caused by temperature variation, climatic variation and vibration during the manufacturing, the installment and the using of the blast furnace. There is a wear-resistant lining installed inside the metal bellows expansion joint, which enables a flexible connection between material distributor and lower sealing valve. Bottom metal bellows expansion joint is usually installed with 2 to 4 bellows, and it could compensate for the deformation of 40-80mm.

The bottom metal bellows expansion joint is made of corrosion-resistant stainless steel plates, and its lining is made of wear-resistant high-chromium materials. Besides that, there are head bolts equipped outside the metal bellows expansion joint, and the head bolts undergo a fully released status, which allows for a stress withstanding for thermal expansion and contraction.