Application

With a good sealing effect, blast furnace pressure equalizing valve is suitable for dealing with nitrogen, raw coal gas and other gas containing dust. Blast furnace pressure equalizing valve is easy to operate. It is applicable for releasing coal gas in the blast furnace and equalizing pressure in the charging system of blast furnace.

Parameters

Nominal pressure: 0.2MPa

Sealing test pressure: 0.22MPa

Strength test pressure: 0.3MPa

Applicable temperature: ≤300 ℃

Applicable medium: nitrogen, coal gas

Oil pressure: 8 -10MPa

Port size: M18×1.5

Proximity limit: IAS2408LA

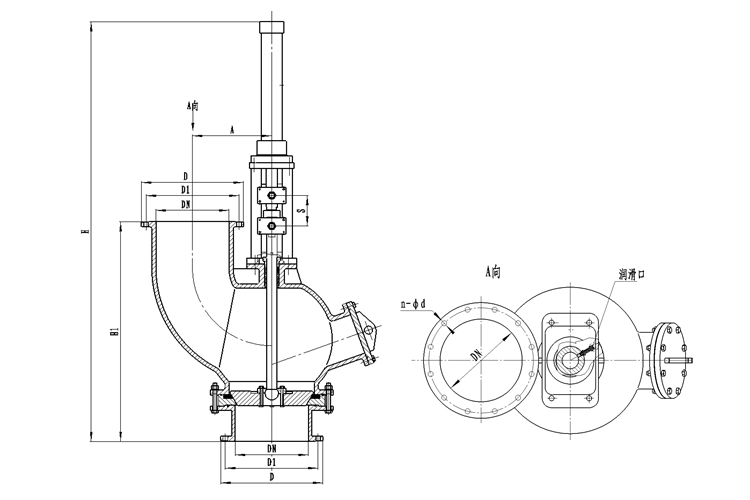

Main Dimensions (Unit: mm)

Main Dimensions (Unit: mm)| DN | D | D1 | n-d | A | H | H1 | S | Cylinder diameter |

| 200 | 320 | 280 | 8-φ18 | 320 | 1652 | 776 | 250 | 80 |

| 250 | 375 | 335 | 12-φ18 | 320 | 1732 | 796 | 250 | 80 |

| 300 | 440 | 395 | 12-φ22 | 360 | 1736 | 850 | 250 | 80 |

| 350 | 490 | 445 | 12-φ22 | 380 | 1930 | 1205 | 280 | 100 |

| 450 | 595 | 550 | 16-φ22 | 530 | 1930 | 1200 | 280 | 100 |

Features

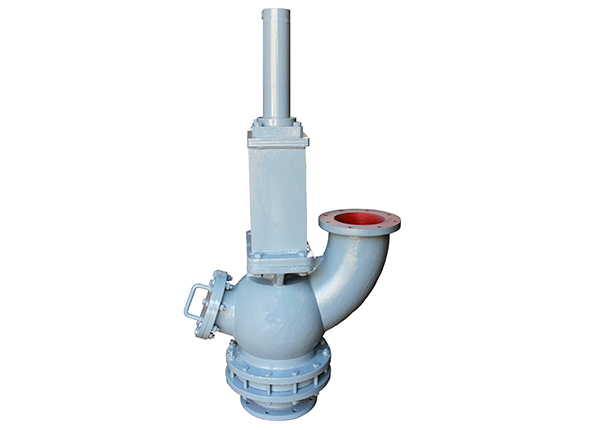

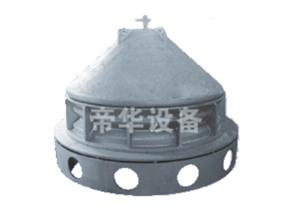

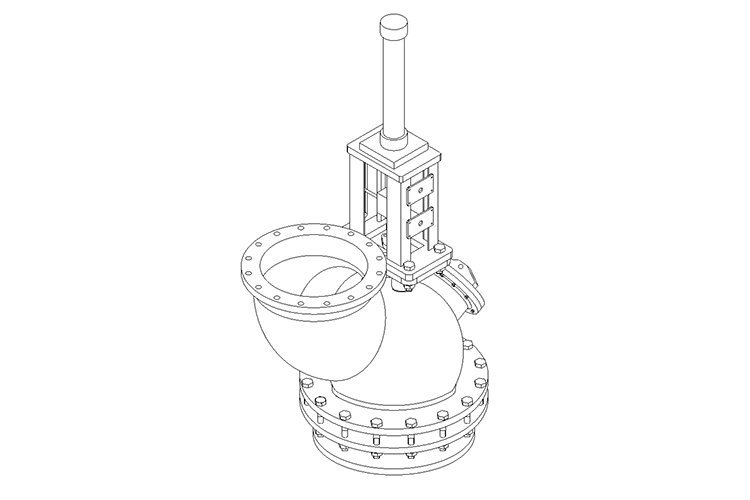

1. Blast furnace pressure equalizing valve is a common-used closed valve. It is composed of valve body, valve seat, valve plate and actuating cylinder.

2. The sealing plate can be opened inside the blast furnace pressure equalizing valve. The surfacing alloy on the sealing surface is featured by good wear resistance. The pressure equalizing valve is also installed with silicone rubber ring to form its composite sealing of hard sealing and soft sealing.

3. Hydraulic cylinder drives valve plate to control the opening and closing of the blast furnace pressure equalizing valve. It can also realize remote automatic control through inputting signal to the program.