Application

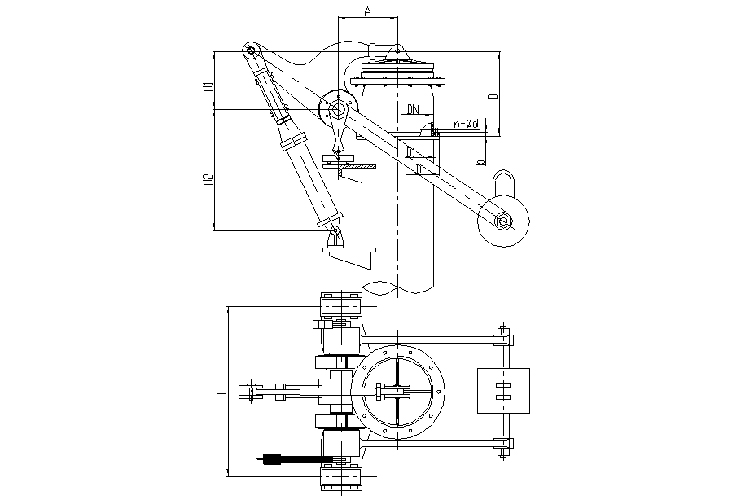

Hydraulic blast furnace top relief valve is used at the top of blast furnace for protecting the equipment at the top of blast furnace. It can also be used as discharge device of industrial furnace gas. Hydraulic blast furnace top relief valve is vertically installed on the pipe. The opening and closing of the hydraulic blast furnace top relief valve is controlled by 8-12MPa hydraulic oil drive linkage mechanism. It is broadly used in steel plants, power plants, cement plants, chemical plants, metallurgic plants, coal mines, paper mills and other mining industries.

Parameters

Nominal pressure: 0.25 Mpa

Sealing test pressure: 0.275 Mpa

Strength test pressure: 0.375Mpa

Applicable temperature: ≤500 ℃

Applicable medium: air, gas containing dust, coal gas

Material of main parts

Valve seat, valve cover: cast steel, sealing surface is under surfacing ZD5MO.

Valve, linkages: welding parts

| DN (mm) | Cylinder Diameter(mm) | Cylinder stroke(mm) | Working pressure (MPa) | Port size |

| 250 ~400 | 80 | 320 | 8 | M27 X 2 |

| 500 ~700 | 100 | 420 | 8 | M33 X 2 |

| 800 ~1000 | 160 | 690 | 12 | M42 X 2 |

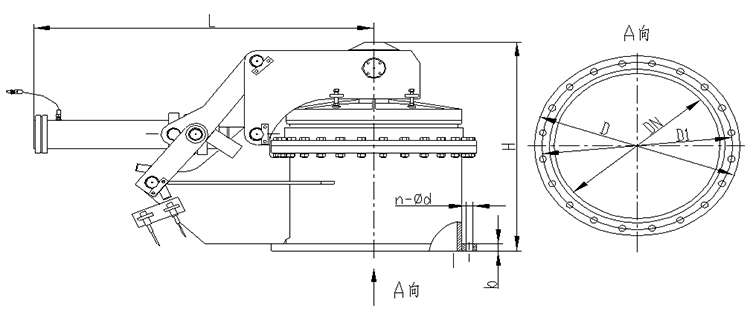

Main Dimensions / Unit: mm

Main Dimensions / Unit: mm| DN | D | D1 | b | H | L | n- φd | Weight(kg) |

| 250 | 375 | 335 | 25 | 620 | 640 | 12-18 | 1010 |

| 300 | 440 | 395 | 25 | 640 | 760 | 12-22 | 1175 |

| 400 | 540 | 495 | 30 | 705 | 970 | 16-22 | 1400 |

| 500 | 645 | 600 | 30 | 810 | 1240 | 20-22 | 1560 |

| 600 | 755 | 705 | 35 | 870 | 1210 | 20-26 | 1795 |

| 700 | 860 | 810 | 35 | 920 | 1810 | 24-26 | 1960 |

| 800 | 975 | 920 | 40 | 1430 | 1940 | 24-30 | 2095 |

| 1000 | 1175 | 1120 | 50 | 1430 | 2060 | 28-30 | 2510 |

Features

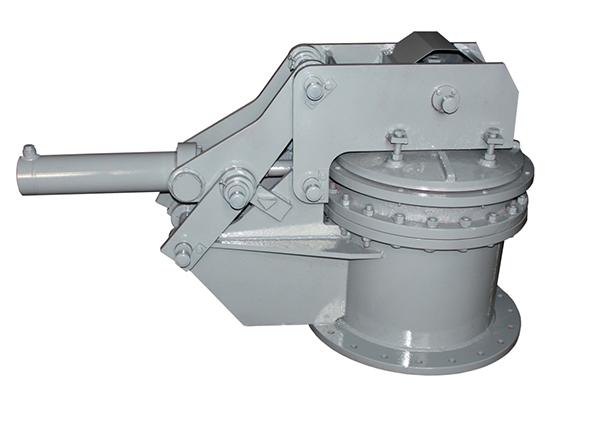

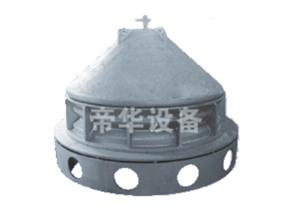

1. Hydraulic blast furnace top relief valve adopts linkage mechanism that is turned over 90 degrees. Hydraulic blast furnace top relief valve is comprised of valve body, valve cover and linkage mechanism.

2. The seal structure is a combination of silicone rubber seal and alloy seal. Hard sealing surface is under surfacing ZD5Mo, and soft sealing material is silicone rubber. The hydraulic blast furnace relief valve has good sealing performance. In the condition of hard sealing, the leakage rate of the relief valve is D class of GB/T13927 standard.

3. Belleville springs on the valve cover enables the valve cover sealing surface and valve seat sealing surface to contact and keep certain pressure between surfaces.

4. The spring preload replaces the original counterweight, so the relief valve features light weight and easy installation. The spring is in the center of the valve cover, so the valve cover is free of tilt force, which improves the sealing effect of blast furnace and extends the service life of relief valve.

5. Self-locking linkage ensures the normal operation of the relief valve on pipes and also facilitates replacement of parts.