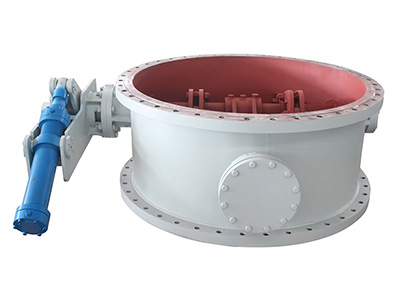

Three-lever valve is an innovative and well-engineered hydraulic valve, featuring a rational design, light weight, low torque for opening and closing, as well as reliable and flexible operation. This valve serves as a stable and dependable airflow cutoff device, effectively regulating the flow and pressure of gases including air, coal gas, and fume within pipelines. The 3-lever valve finds extensive applications across various sectors such as metallurgy, mining, coal, and chemical industries.

Features

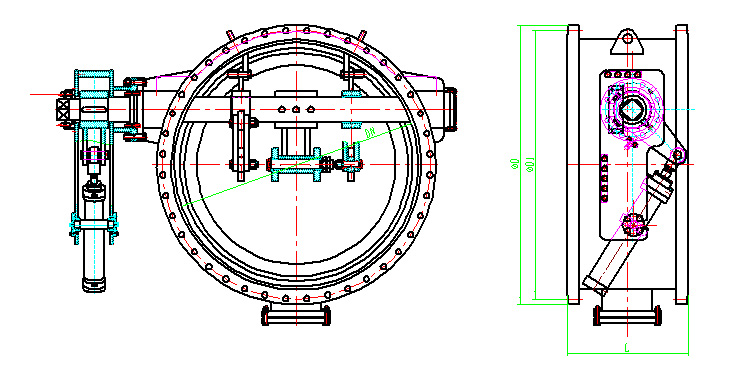

1.Made of welded steel plates, the three-lever valve offers light weight, easy operation and maintenance.

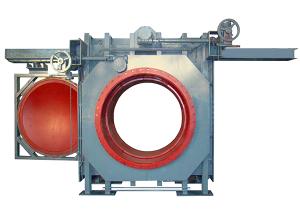

2.3-lever valve utilizes an external drive connecting rod with a four-link mechanism driven by the valve stem, enabling the valve plate to move along the designed trajectory for opening and closing.

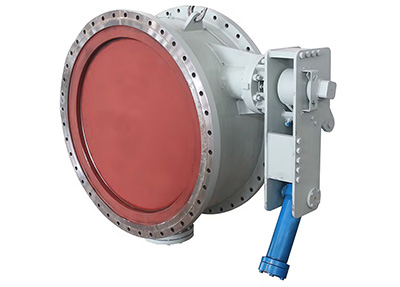

3.During the initial opening and closing of the valve, the valve plate undergoes translational motion, which prevents any form of shear compression or friction on the valve seat, ensuring safety, reliability, and long service life.

4.The valve seat seal is positioned on the vertical plane, effectively preventing any damage to the sealing surface caused by solid particles in the pipeline during switching, ensuring reliable valve operation.

5.The valve is equipped with bearings at both ends of the shaft, ensuring smooth movement without sticking or resistance under working conditions.

6.During opening, a maximum pressure difference on both sides of the valve is limited to prevent the movement mechanism from being impacted by the high-pressure differential airflow.

Technical Parameters

Medium: Coal gas, air, fume, and other gases

Nominal pressure: 0.6 MPa

Working temperature: ≤450℃

Leakage rate: Conforms to EN12266-2, Class B

Allowable pressure difference during operation: ≤0.02 MPa

Rotation angle: 90°

Switching time: ≤20s

| Part | Valve body/valve plate | Sealing surface | Valve stem |

| Material | Q345R | Hardfacing alloy | 2Gr13 |