Hot stove valve is widely used in the medium-high temperature pipeline as hot stove valve, flue valve and backdraft valve. (Backdraft in blast furnace refers to the operation that when air is cut off, the coal gas residue is discharged through hot air pipe to hot stove or the special chimney.)

Hot stove valve adopts welded structure, forced water cooling system, and forced compression seal. The working temperature of hot stove valve is ≦1350℃. It can meet the special requirement for sealed valve without hot air pressure.

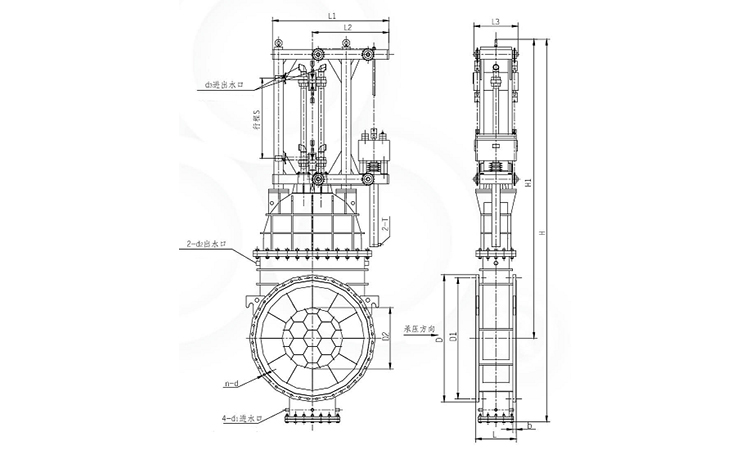

DR43R-4 high temperature hot stove valve uses a welded structure. The material of sealing surface is 1Cr18Ni9Ti. There are heat-resistant interlayers at both sides of the valve plate. DR43R-4 high temperature hot stove valve is commonly used in high temperature pipelines as chimney valve, backdraft valve and flue valve.

DR43R-4 high temperature hot stove valve adopts a drive system to control the opening and closing of the valve. It ban be equipped with manual hoisting device and hydraulic lifting device.

Technical Parameters| Nominal pressure | 0.4MPa |

| Working temperature | ≤1350 ℃ |

| Allowable pressure difference during operation | ≤0.01MPa |

| Cooling water pressure | 0.4-0.6MPa |

| Temperature difference (inlet/outlet) | ≤10 ℃ |

| Material | 20G, 1Cr18Ni9Ti |

| Medium | Hot air, fume |

| DN | D | D1 | D2 | L | b | N-d | d1 | d2 | d3 | Hmax | H1 | H2 | Hole | Stroke |

| 500 | 1220 | 1140 | 420 | 550 | 40 | 30-33 | R11/4 | R2 | G2 | 4115 | 820 | 1665 | P | 825 |

| 700 | 1420 | 1340 | 620 | 550 | 40 | 36-33 | R11/4 | R2 | G21/2 | 4750 | 1030 | 1975 | P | 970 |

| 900 | 1700 | 1620 | 800 | 600 | 50 | 40-34 | R11/4 | R2 | G21/2 | 5445 | 1210 | 2285 | T | 1175 |

| 1000 | 1870 | 1770 | 1000 | 600 | 50 | 48-34 | R11/4 | R2 | G21/2 | 5655 | 1215 | 2390 | T | 1275 |

| 1100 | 1900 | 1780 | 1100 | 650 | 60 | 48-34 | R11/2 | R21/2 | G21/2 | 6005 | 1270 | 2545 | T | 1375 |

| 1200 | 2280 | 2180 | 1200 | 700 | 60 | 48-34 | R11/2 | R21/2 | R21/2 | 6405 | 1420 | 2750 | P | 1530 |

| 1300 | 2600 | 2430 | 1160 | 700 | 60 | 52-45 | R11/2 | R21/2 | G21/2 | 6910 | 1585 | 2975 | T | 1700 |

| 1500 | 2810 | 2720 | 1500 | 700 | 70 | 52-56 | R11/2 | R21/2 | G21/2 | 7730 | 1705 | 3355 | P | 1900 |

| 1700 | 2740 | 2640 | 1500 | 700 | 70 | 56-46 | R2 | R3 | G3 | 7910 | 1610 | 3490 | P | 2000 |

| 1800 | 2960 | 2850 | 1600 | 700 | 70 | 60-60 | R2 | R3 | G3 | 8275 | 1720 | 3655 | P | 2000 |

Note: Hole position "T" stand for the hole d is at the vertical center line. Hole position "P" stand for the hole d is symmetric to the vertical center line.

Technical Parameters

Technical Parameters | DN | 500 | 700 | 900 | 1000 | 1100 | 1200 | 1300 | 1500 | 1700 | 1800 | |

| Weight(KG) | 2900 | 3820 | 5700 | 6500 | 7400 | 10700 | 11000 | 17400 | 17450 | 21700 | |

| Flow rate m3/h | Valve body | 25 | 35 | 45 | 50 | 55 | 55 | 55 | 60 | 60 | 80 |

| Valve plate | 7 | 15 | 20 | 22 | 25 | 25 | 30 | 40 | 45 | 50 | |

| Sealing surface material | 1Cr18Ni9Ti | ||||||||||

| Refractory material | RF-1 | ||||||||||

Structure Characteristics

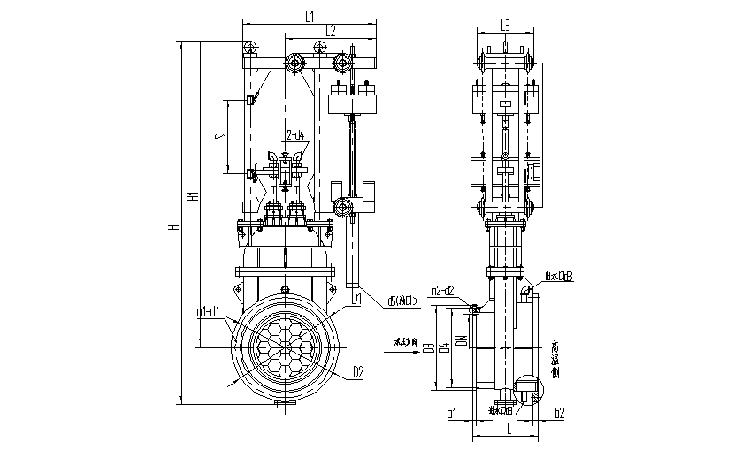

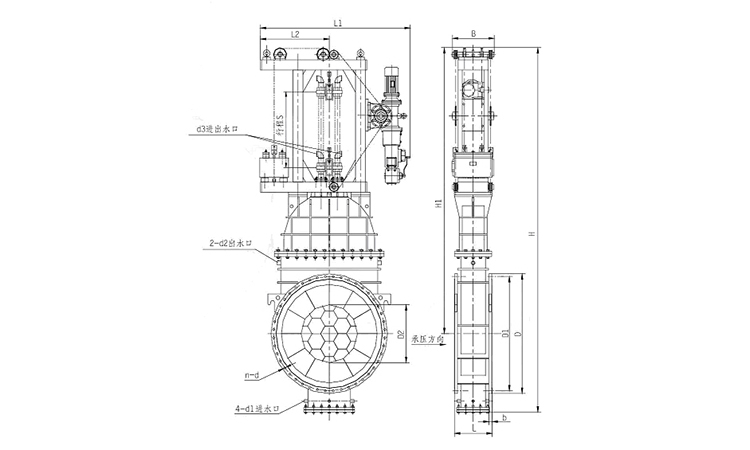

DR743R-4 high temperature hot stove valve adopts a welded structure. The material of sealing surface is 1Cr18Ni9Ti. There are heat-resistant interlayers at both sides of the valve plate. DR743R-4 high temperature hot stove valve is broadly applied in high temperature pipelines as chimney valve, backdraft valve, cold blast mixing shut-off valve and flue valve.

Drive: hydraulic drive, with a signal switch.

Type of opening and closing: forced opening and closing

| Nominal pressure | 0.4MPa |

| Working temperature | ≤1350 ℃ |

| Allowable pressure difference during operation | ≤0.01MPa |

| Cooling water pressure | 0.4-0.6MPa |

| Temperature difference (inlet/outlet) | ≤10 ℃ |

| Material | 20G, 1Cr18Ni9Ti |

| Medium | Hot air, fume |

| DN | D | D1 | D2 | L | L1 | L2 | L3 | b | H | H1 | N-d | d1 | d2 | d3 | Hole |

| 500 | 1220 | 1140 | 420 | 550 | 1230 | 793 | 573 | 50 | 4370 | 3550 | 30-33 | R11/4 | R2 | G3 | P |

| 700 | 1420 | 1340 | 620 | 550 | 1518 | 1038 | 710 | 40 | 5090 | 4060 | 36-33 | R11/4 | R2 | G21/2 | P |

| 900 | 1700 | 1620 | 800 | 600 | 1768 | 1178 | 710 | 50 | 5710 | 4500 | 40-34 | R11/4 | R2 | G21/2 | T |

| 1000 | 1870 | 1770 | 1000 | 600 | 1806 | 1216 | 710 | 50 | 6000 | 4785 | 48-34 | R11/4 | R2 | G21/2 | T |

| 1100 | 1900 | 1780 | 1100 | 650 | 1836 | 1246 | 710 | 60 | 6355 | 5085 | 48-34 | R11/2 | R21/2 | G21/2 | T |

| 1200 | 2280 | 2180 | 1200 | 700 | 1930 | 1330 | 710 | 60 | 6825 | 5350 | 48-34 | R11/2 | R21/2 | R21/2 | P |

| 1300 | 2600 | 2430 | 1300 | 700 | 2020 | 1420 | 710 | 60 | 7310 | 5725 | 52-45 | R11/2 | R21/2 | R21/2 | T |

| 1500 | 2810 | 2720 | 1500 | 700 | 2210 | 1610 | 710 | 70 | 8080 | 6375 | 52-56 | R11/2 | R21/2 | G21/2 | P |

| 1700 | 2740 | 2640 | 1500 | 700 | 2210 | 1610 | 710 | 70 | 8080 | 6375 | 56-46 | R2 | R3 | R3 | P |

| 1800 | 2960 | 2850 | 1600 | 700 | 2430 | 1620 | 710 | 70 | 8160 | 6550 | 60-60 | R2 | R3 | R3 | P |

Note: Hole position "T" stands for that the hole d is at the vertical center line. Hole position "P" stands for that the hole d is symmetric to the vertical center line.

Technical Parameters

Technical Parameters | DN | 500 | 700 | 900 | 1000 | 1100 | 1200 | 1300 | 1500 | 1700 | 1800 | |

| Weight(KG) | 3920 | 4925 | 6900 | 7500 | 8800 | 10700 | 12500 | 18900 | 18950 | 21890 | |

| Stroke | 825 | 900 | 1175 | 1275 | 1375 | 1530 | 1700 | 1900 | 2000 | 2100 | |

| Flow rate m3/h | Valve body | 25 | 35 | 45 | 50 | 55 | 55 | 55 | 60 | 60 | 80 |

| Valve plate | 7 | 15 | 20 | 22 | 25 | 25 | 30 | 40 | 45 | 50 | |

| Cylinder Diameter | 50 | 50 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| Port size | M18*1.5 | M27*2 | |||||||||

| Hydraulic pressure (MPa) | 8 | ||||||||||

| Sealing surface material | 1Cr18Ni9Ti | ||||||||||

| Limit switch | LXP1-120/1UA | ||||||||||

| Refractory materials | RF-1 | ||||||||||

Structure Characteristics

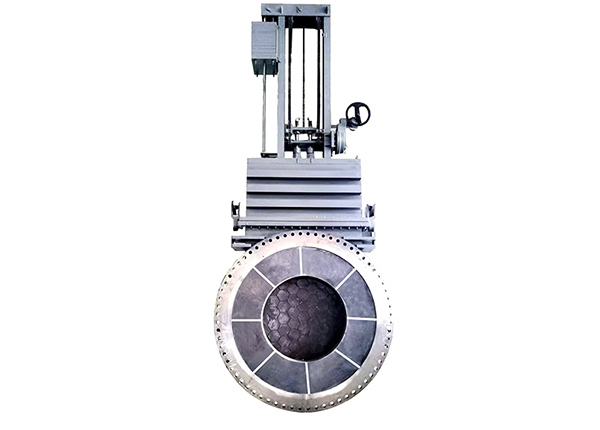

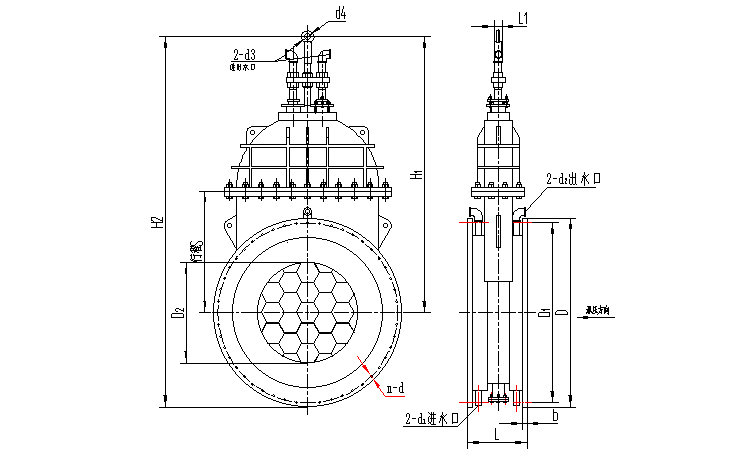

DR943R-4 high temperature hot stove valve has a welded structure. The material of sealing surface is 1Cr18Ni9Ti. There are heat-resistant interlayers at both sides of the valve plate. DR943R-4 high temperature hot stove valve is broadly applied in high temperature pipelines as chimney valve, backdraft valve, cold blast mixing shut-off valve and flue valve.

Drive: Electric drive

Type of opening and closing: forced opening and closing

| Nominal pressure | 0.4MPa |

| Working temperature | ≤1350 ℃ |

| Allowable pressure difference during operation | ≤0.01MPa |

| cooling water pressure | 0.4-0.6MPa |

| Temperature difference (inlet/outlet) | ≤10 ℃ |

| Material | 20G, 1Cr18Ni9Ti |

| Medium | Hot air, fume |

| DN | D | D1 | D2 | L | L1 | L2 | L3 | b | H | H1 | N-d | d1 | d2 | d3 | Hole |

| 500 | 1220 | 1140 | 420 | 550 | 1994 | 940 | 575 | 50 | 4500 | 3680 | 30-33 | R11/4 | R2 | G3 | P |

| 700 | 1420 | 1340 | 620 | 550 | 2114 | 1000 | 710 | 40 | 5090 | 4060 | 36-33 | R11/4 | R2 | G21/2 | P |

| 900 | 1700 | 1620 | 800 | 600 | 2314 | 1100 | 710 | 50 | 5790 | 4580 | 40-34 | R11/4 | R2 | G21/2 | T |

| 1000 | 1870 | 1770 | 1000 | 600 | 2314 | 1100 | 710 | 50 | 6000 | 4785 | 48-34 | R11/4 | R2 | G21/2 | T |

| 1100 | 1900 | 1780 | 1100 | 650 | 2314 | 1100 | 710 | 60 | 6350 | 5080 | 48-34 | R11/2 | R21/2 | G21/2 | T |

| 1200 | 2280 | 2180 | 1200 | 700 | 2314 | 1100 | 710 | 60 | 6800 | 5375 | 48-34 | R11/2 | R21/2 | R21/2 | P |

| 1300 | 2600 | 2430 | 1300 | 700 | 2020 | 1420 | 710 | 60 | 7310 | 5725 | 52-45 | R11/2 | R21/2 | R21/2 | T |

| 1500 | 2810 | 2720 | 1500 | 700 | 2724 | 1300 | 710 | 70 | 8070 | 6365 | 52-56 | R11/2 | R21/2 | G21/2 | P |

| 1700 | 2740 | 2640 | 1500 | 700 | 2314 | 1100 | 710 | 70 | 8070 | 6356 | 56-46 | R2 | R3 | R3 | P |

| 1800 | 2960 | 2850 | 1600 | 700 | 2724 | 1300 | 710 | 70 | 8150 | 6540 | 60-60 | R2 | R3 | R3 | P |

Note: Hole position "T" stands for that the hole d is at the vertical center line. Hole position "P" stands for that the hole d is symmetric to the vertical center line.

Technical Parameters

Technical Parameters | DN | 500 | 700 | 900 | 1000 | 1100 | 1200 | 1300 | 1500 | 1700 | 1800 | |

| Weight(KG) | 3920 | 4925 | 6900 | 7500 | 8800 | 10700 | 12500 | 18900 | 19200 | 20760 | |

| Stroke | 825 | 970 | 1175 | 1275 | 1375 | 1530 | 1700 | 1900 | 2000 | 2000 | |

| Cooling water Flow rate m3/h | Valve body | 25 | 35 | 45 | 50 | 55 | 55 | 55 | 60 | 60 | 80 |

| Valve plate | 7 | 15 | 20 | 22 | 25 | 25 | 30 | 40 | 45 | 50 | |

| Electric actuator | 380V 3 Phase 50HZ | ||||||||||

| Sealing surface material | 1Cr18Ni9Ti | ||||||||||

| Limit switch | LXP1-120/1UA | ||||||||||

| Refractory material | RF-1 | ||||||||||

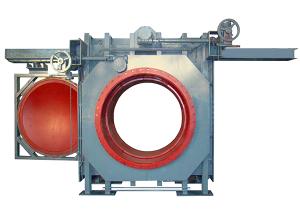

DR42PH-4 non driving blast admixing shut off valve is appropriate for hot stove system of large and medium-sized blast furnace as hot air valve, chimney valve and high temperature flue valve, etc. DR42PH-4 non driving blast admixing shut off valve is characterized by simple structure, large cooling water jacket and low requirement for water quality.

Main Structure Dimension /Unit: mm| DN | D0 | D | D1 | L | n-d | b | d1 | d2 | d3 | d4 | H1 | H2 | L1 | S |

| 500 | 526 | 1180 | 1120 | 320 | 28-30 | 30 | 2-R11 /4 | 2-R1 | Rc11/2 | 80 | 1427 | 2350 | 25 | 610 |

| 700 | 720 | 1550 | 1470 | 450 | 42-27 | 40 | 4-R2 | 4-R11/2 | Rc2 | 80 | 2305 | 3300 | 30 | 800 |

| 900 | 900 | 1640 | 1560 | 500 | 48-27 | 40 | 4-R2 | 4-R11/2 | Rc21/2 | 49 | 2475 | 3500 | 60 | 1000 |

| 1100 | 1100 | 2100 | 2000 | 530 | 48-34 | 50 | 4-R2 | 4-R11/2 | Rc21/2 | 50 | 3100 | 4480 | 60 | 1300 |

Structure Characteristics

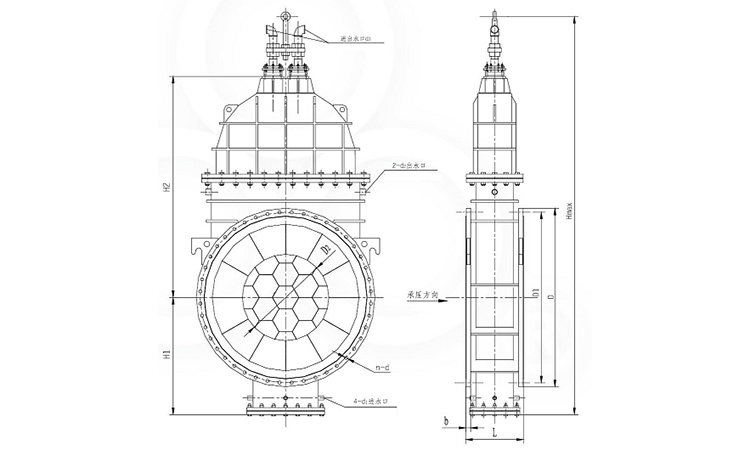

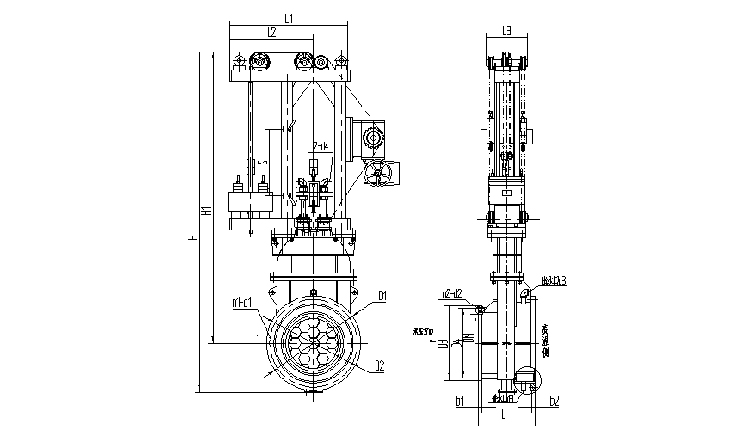

DR942PH-4 electric blast admixing shut off valve has a welded structure. The material of sealing surface is 1Cr18Ni9Ti. The valve plate is water cooled, and at the high temperature side of the valve plate, there is heat-resistant interlayer. The cooling system is equipped on the connecting side of the valve body and the hot air duct. The valve rod and valve cover adopt floating seal. DR942PH-4 electric blast admixing shut off valve is electrically driven. It is suitable for blast furnace hot stove system as blast admixing shut off valve.

| Nominal pressure | 0.4 |

| Working temperature | High temperature ≤1000 ℃, Low temperature ≤500 ℃ |

| Allowable pressure difference during operation | ≤0.01MPa |

| Cooling water pressure | 0.4-0.6MPa |

| Temperature difference (inlet/outlet) | ≤10 ℃ |

| Material | Q235, 1Cr18Ni9Ti |

| Medium | Air, fume, coal gas |

| DN | D1 | D2 | D3 | D4 | H | H1 | L | b1 | b2 | n1-d1 | n1-n2 | Hole |

| 600 | 990 | 920 | 780 | 730 | 325 | 2745 | 600 | 35 | 45 | 24-30 | 20-26 | P |

| 700 | 1080 | 1000 | 900 | 840 | 3665 | 3090 | 530 | 35 | 45 | 30-34 | 28-28 | P |

| 1000 | 1510 | 1410 | 1220 | 1150 | 4875 | 4025 | 590 | 40 | 45 | 36-33 | 24-33 | P |

Structure Characteristics

DR742PH-4 hydraulic blast admixing shut off valve uses a welded structure. The material of sealing surface is 1Cr18Ni9Ti. The valve plate is water cooled, and at the high temperature side of the valve plate, there is heat-resistant interlayer. The cooling system is equipped on the connecting side of the valve body and the hot air duct. The valve rod and valve cover adopt floating seal. DR742PH-4 hydraulic blast admixing shut off valve is hydraulically driven. It is suitable for blast furnace hot stove system as blast admixing shut off valve.

| Nominal pressure | 0.4 |

| Working temperature | High temperature ≤1000 ℃ Low temperature ≤500 ℃ |

| Allowable pressure difference during operation | ≤0.01MPa |

| Cooling water pressure | 0.4-0.6MPa |

| Temperature difference (inlet/outlet) | ≤10 ℃ |

| Material | Q235, 1Cr18Ni9Ti |

| Applicable medium | Air, fume, coal gas |

| DN | D1 | D2 | D3 | D4 | H | H1 | L | b1 | b2 | n1-d1 | n1-n2 | Hole |

| 600 | 990 | 920 | 780 | 730 | 3325 | 2745 | 600 | 35 | 45 | 24-30 | 20-26 | P |

| 700 | 1080 | 1000 | 900 | 840 | 3665 | 3090 | 530 | 35 | 45 | 30-34 | 28-28 | P |

| 1000 | 1510 | 1410 | 1220 | 1150 | 4875 | 4025 | 590 | 40 | 45 | 36-33 | 24-33 | P |