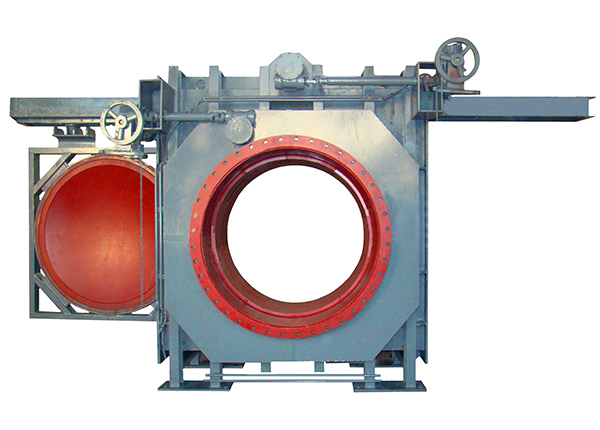

Blast furnace electric slide gate valve is mainly used in gas pipelines. The replacement of the sealing rubber ring, maintenance and replacement of electric actuator and maintenance of valve parts are carried out outside of the blast furnace electric slide gate valve without affecting the normal operation of the valve. The open structure of the valve facilitates maintenance.

Technical Parameters| Nominal diameter | DN1000-2400mm | DN2600-3000mm | DN3200-3400mm |

| Working temperature | ≤250 ℃ (250 ℃~450 ℃/ cooling water required) | ≤250 ℃ (250 ℃~450 ℃/ cooling water required) | ≤250 ℃ (250 ℃~450 ℃ / cooling water required) |

| Medium/Design pressure | 0.25MPa | 0.15MPa | 0.05MPa |

| Allowable pressure difference during operation | 30KPa | 30KPa | 30KPa |

| Medium | Coal gas, air, gas with dust | Coal gas, air, gas with dust | Coal gas, air, gas with dust |

| Leakage | 0 | 0 | 0 |

| Operating time | ≤90 S | ≤120 S | ≤160 S |

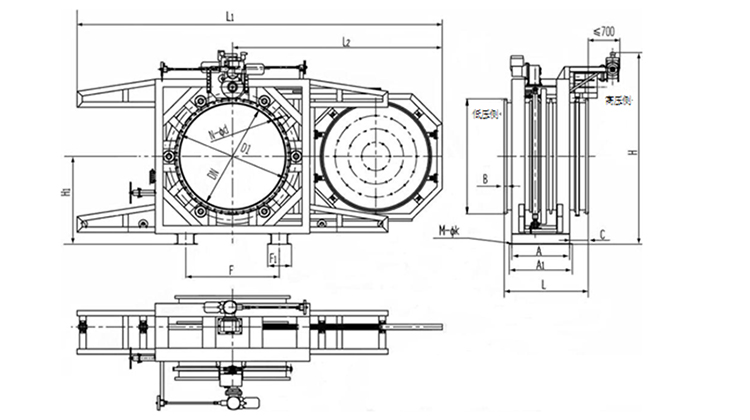

| DN | D | D1 | L | B | H | H1 | N- φd | L1 | L2 | A | A1 | C | F | F1 | M- φK | Weight (KG) | Motor power (KW) | Nominal pressure | ||

| Slide | Clamping | |||||||||||||||||||

| 1200 | 1375 | 1320 | 1400 | 35 | 2800 | 1165 | 32-φ30 | 4600 | 2580 | 925 | 1025 | 330 | 1160 | 400 | 4- φ33 | ≈7500 | 0.75 | 3 | 0.05 | 0.25 |

| 1400 | 1575 | 1520 | 1400 | 35 | 3044 | 1285 | 36-φ30 | 5200 | 2880 | 925 | 1025 | 330 | 1360 | 400 | 4- φ33 | ≈9000 | 1.1 | 3 | 0.05 | 0.25 |

| 1600 | 1790 | 1730 | 1400 | 35 | 3245 | 1385 | 40-φ30 | 5676 | 3306 | 1005 | 1105 | 300 | 1560 | 500 | 4- φ33 | ≈10500 | 1.1 | 3 | 0.05 | 0.25 |

| 1800 | 1990 | 1930 | 1600 | 40 | 3400 | 1480 | 44-φ30 | 6220 | 3520 | 1100 | 1200 | 355 | 1760 | 500 | 4- φ33 | ≈11500 | 1.1 | 4 | 0.05 | 0.25 |

| 2000 | 2190 | 2130 | 1600 | 40 | 3685 | 1670 | 48-φ30 | 6860 | 3990 | 1100 | 1200 | 355 | 1780 | 500 | 4- φ33 | ≈14000 | 1.1 | 4 | 0.05 | 0.25 |

| 2200 | 2405 | 2340 | 1600 | 40 | 4110 | 1770 | 52-φ33 | 7450 | 4250 | 1100 | 1200 | 355 | 1980 | 500 | 4- φ33 | ≈15000 | 1.5 | 4 | 0.05 | 0.25 |

| 2400 | 2605 | 2540 | 1600 | 40 | 4312 | 2050 | 56-φ33 | 7950 | 4550 | 1100 | 1200 | 355 | 2320 | 500 | 4- φ33 | ≈17000 | 1.5 | 4 | 0.05 | 0.15 |

| 2400 | 2605 | 2540 | 1800 | 40 | 4312 | 2050 | 56-φ33 | 7950 | 4670 | 1310 | 1410 | 375 | 2320 | 500 | 4- φ33 | ≈19500 | 1.5 | 4 | 0.25 | 0.25 |

| 2600 | 2805 | 2740 | 1800 | 50 | 4315 | 2100 | 60-φ33 | 8515 | 4820 | 1310 | 1410 | 375 | 2520 | 600 | 4- φ36 | ≈19000 | 1.5 | 5.5 | 0.05 | 0.1 |

| 2800 | 3030 | 2960 | 1800 | 50 | 4554 | 2200 | 64-φ36 | 9015 | 5120 | 1310 | 1410 | 375 | 2720 | 600 | 4- φ36 | ≈20000 | 1.5 | 5.5 | 0.05 | 0.1 |

| 3000 | 3230 | 3160 | 1800 | 50 | 4900 | 2300 | 68-φ36 | 9485 | 5479 | 1310 | 1410 | 375 | 2920 | 600 | 4- φ36 | ≈22000 | 1.5 | 5.5 | 0.05 | 0.1 |

| 3200 | 3430 | 3360 | 2200 | 60 | 5554 | 2500 | 72-φ36 | 9800 | 5700 | 1500 | 1600 | 380 | 3120 | 800 | 4- φ36 | ≈25000 | 2.2 | 7.5 | 0.05 | |

| 3400 | 3630 | 3560 | 2200 | 60 | 5900 | 2600 | 76-φ36 | 10200 | 5900 | 1500 | 1600 | 380 | 3320 | 800 | 4- φ36 | ≈26500 | 2.2 | 7.5 | 0.05 | |

| 3600 | 3840 | 3770 | 2200 | 60 | 6100 | 2700 | 80-φ36 | 10600 | 6100 | 1500 | 1600 | 380 | 3520 | 800 | 4- φ36 | ≈28500 | 4 | 7.5 | 0.05 | |

Note: We supply one or two types of pressure for customer's option. Please refer to the details of outer dimensions of the valve in the above table.

Features

1. Blast furnace electric slide gate valve adopts outdoor ZA type, explosion-proof electric device.

2. The electric device is equipped with sprocket. In the case of power failure, sprocket is manually switched to carry out the operation on the ground through manual-electric conversion mechanism on the electric device.

3. The two electric devices of the valve body are furnished with control system. The control systems can finish on-site control and remote control through connecting to PLC system. The blast furnace electric gate valve is designed to have explosion-proof terminals.

4. Blast furnace electric slide gate valve can be equipped with explosion-proof control cabinet to realize on-site control and remote control through connecting to PLC system. The control distance is over 10 meters.